The use of 1.5 cubic meters of self-loading mixers has changed the traditional way of concrete self-manufacturing. It combines the dual functions of carrying and mixing, and it can carry out stirring actions while transporting concrete.

InquiryThe use of 1.5 cubic meters of self-loading mixers has changed the traditional way of concrete self-manufacturing. It combines the dual functions of carrying and mixing, and it can carry out stirring actions while transporting concrete. The 1.5 cubic meter self-loading mixer is based on the above-mentioned work characteristics, and can allow proper extension of the transport distance or delivery time under the condition of ensuring the quality of the transported concrete. The 1.5 cubic meter self-loading mixer truck can usually adopt different working methods according to different conditions such as the length of concrete transport distance, on-site construction conditions, and the ratio and quality requirements of concrete.

1.5 cubic meter self-loading mixer cleaning method:

1. Rinse the feed inlet with water before each charge to keep the feed inlet moist while charging;

2. Remember to drain the concrete tank before loading the next time;

3. Thoroughly clean the concrete tank and the surrounding of the inlet and outlet at the time of daily work to ensure that there is no cement and concrete agglomeration.

4. Fill the cleaning water tank that comes with the vehicle while loading;

5. Rinse the feed inlet after filling and clean the remaining concrete near the feed inlet;

6. After unloading at the construction site, flush the discharge chute, and then add 30 to 40L of cleaning water to the concrete tank; keep the concrete tank rotating at a slow speed while returning the vehicle.

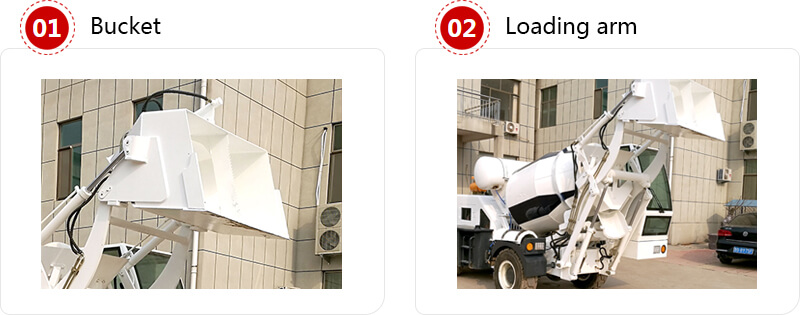

Loading: Based on a unique, hinged hydraulic shovel, the ingredients can be loaded easily and accurately. The built-in blade of the bucket automatically cuts through the cement bags to avoid wasted material. All ingredients can smoothly and quickly enter the mixing drum from the bucket.

Stirring: After the aggregates and cement enter the mixing bowl, they can be perfectly mixed by the self-pressurizing water stream in the double bucket. The unique double screw blade guarantees the mixing quality and the concrete quality and is equipped with an electronic weighing system.

Delivery: Four-wheel drive chassis, full hydraulic transmission, perfectly adapted to all kinds of complex terrain, can be ramped up to 30° when fully loaded.

Discharging: The operator pours the concrete through a 270° rotation agitator barrel using an operating lever to lift the concrete 2m high around the vehicle.

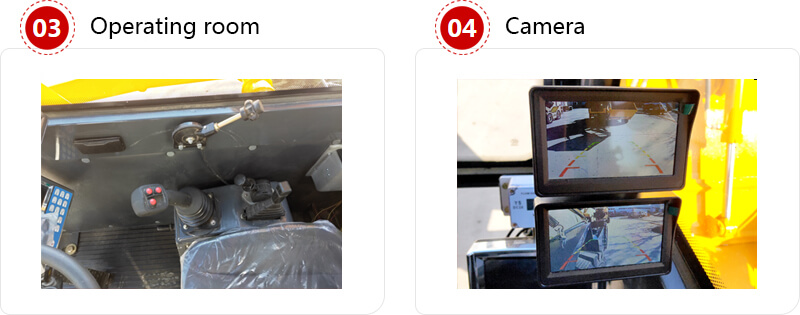

Operation: A fully equipped cab with pilot operated levers designed according to ergonomic principles allows the driver to control all major operations with a single handle.

Safety: equipped with anti-rolling – anti-falling object protection system so that the equipment can provide full protection for drivers in harsh environments.