The 35 concrete mixing plant is a small concrete mixing plant and is often referred to as the 35 plant by customers. This set of concrete mixing plant production line configuration mainly consists of main machine, batching machine, screw conveyor and other related products.

InquiryHZS35 concrete mixing station is a small model concrete mixing station and is often called 35 stations by customers. The production line configuration of the concrete mixing plant consists of host, batching machine, screw conveyor and other related products. Its theoretical productivity is 35m3/h. The concrete mixing station is mainly divided into gravel feeding, powder feeding, water and admixtures. The four parts of feeding, transmission, stirring and storage, the whole body of the equipment adopts the integral steel structure casting. The high-quality H-shaped steel not only has beautiful appearance, but also strengthens the overall structural strength of the concrete mixing plant. The equipment is easy to install and can be applied to various complicated Terrain structure.

JIANXIN HZS35 concrete mixing station has good stirring performance. The equipment adopts JS750 spiral twin-shaft forced mixing main machine to discharge 0.75m3 each time, not only strong mixing performance, but also can achieve good performance for dry hard, plastic and various proportions of concrete. The stirring effect. The batching machine will use the PLD1200 three-bin batching machine. The cement is stored in the cement warehouse, conveyed by the screw conveyor and measured by the cement scale. The equipment is applicable to small and medium-sized construction projects, prefabricated parts factories and commercial concrete production plants.

1、Mixer system

JS750 concrete mixer mixing system consists of: motor, belt wheel, reducer, open gear, agitator, oil supply device and other components.Is a high efficiency model, very wide application.The design structure of the product is reasonable, the layout is novel, the technology is advanced, the stirring is even, the use and maintenance is convenient.

2、Mixer system

The mixing system of the MPC750 vertical shaft planetary mixer is composed of: the mixing arm and its blades make planetary motion, the mixing track is continuous, the mixing motion is violent, and the homogeneity is good; the angle of the mixing blade is reasonable, the mixing efficiency is high, and the wear of the liner and blades is reduced.

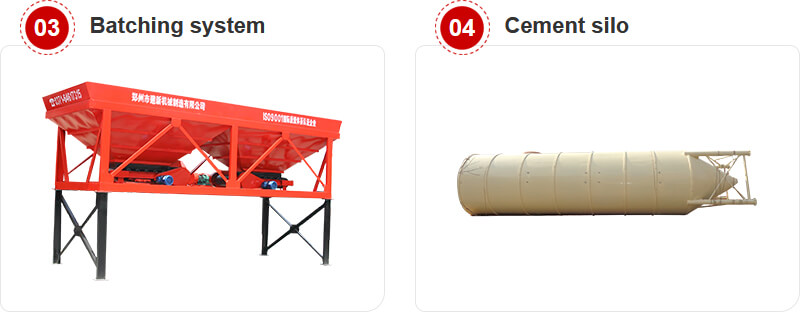

3、Batching system

The PLD1200 concrete batching machine is used in the 35cbm concrete batching plant. The machine adopts a sand and gravel batching device loaded by a loader or a belt conveyor. It can load two to four different materials and be used with various types of mixers and other metering devices to form a fully automatic and semi-automatic mixing plant.

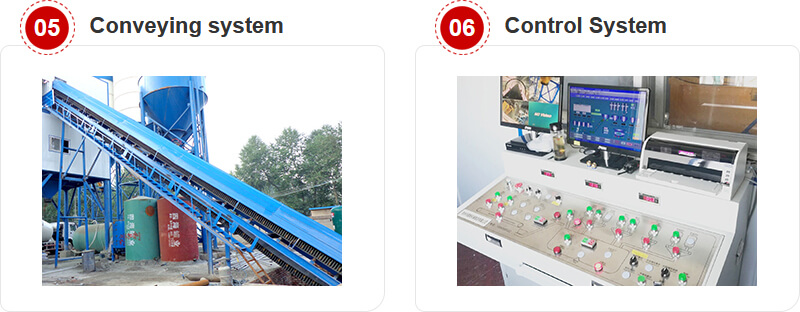

4、Cement silo

The cement silo is divided into three types: flake cement silo, integral cement silo, and horizontal cement silo. in order to prevent the powder from arching, an arch breaking device is installed at the cone part of the silo; it can be designed as a bolted cement silo, which is convenient to transport and easy to use.

5、Conveying system

The aggregate conveying system adopts the lifting bucket feeding method. The big advantage is that it occupies a small space and saves land resources. The belt conveyor is an ideal efficient continuous transportation equipment, which has the advantages of long transportation distance, large transportation volume, continuous transportation.

6、Control system

The core of 35cbm concrete mixing plant is the control system. The whole machine adopts computer control, which can be controlled automatically or manually. The operation is simple and easy to master. Dynamic panel display can clearly show the operation of each component, and can store and print report data.