The theoretical productivity of the HZS60 concrete mixing plant equipment is 60 cubic meters per hour, which occupies a small space, uses less equipment, and is easy to maintain. It can be equipped with a performance independent control room, making the equipment easy and safe to operate.

InquiryThe HZS60 Concrete Mixing Plant is also called the 60 Commercial Mixing Plant. It is a batch-type forced mixing system designed by our company based on the agitation building, which is designed with full consideration of appearance, maintenance, novel and unique structure, elegant appearance, and generous lifting of all materials. The mixing station is the same as the mixing building.

The theoretical productivity of the new HZS60 concrete mixing plant equipment is 60 cubic meters per hour; the main machine of the 60 mixing station is the JS1000 type forced mixer with nominal capacity of 1000L; the batching capacity of the batching machine is 1600L, the maximum production rate of the screw conveyor is 80t/h, aggregate The maximum particle diameter is 80mm, the capacity of the aggregate bin is 51 cubic meters; the range and accuracy of cement weighing (0~900)±1%kg, the range and precision of admixture weighing (0~20)±1%kg, aggregate The weighing range and accuracy are 0×3000±2%. Plus Occupies small space, uses less equipment, and is easy to maintain. It can be equipped with independent control room for performance, making the equipment easy to operate and safe, and it can produce high-quality and high-efficiency concrete under the condition of accurate metering of batching machine. Secondly, the belt feeding system and the waiting bins contain cleaning devices, and they have handrails for overhauling the aisles to facilitate timely cleaning and inspection, which is conducive to the maintenance of the equipment.

1、Mixer system

The 1000 concrete mixer is a medium-sized concrete mixer, mainly suitable for large and medium-sized building construction, roads and bridges, and prefabricated plants for the production of concrete products. It is a kind of forced horizontal shaft mixer, which can not only mix dry hard concrete, but also mix light aggregate concrete. It is a multifunctional mixer.

2、Mixer system

The MPC1000 vertical shaft planetary mixer is composed of: the mixing arm and its blades make planetary motion, the mixing track is continuous, the mixing motion is violent, and the homogeneity is good; The bottom blade cleans the bottom material, and the side blade cleans the side material, and it is with automatic cleaning function.

3、Batching system

The batching device of PLD1600 concrete batching machine adopts belt conveyor feeding or loader feeding method to effectively ensure the accuracy of the mixing ratio of cement/sand/stone or more than three kinds of materials. The main models are PLD1600 two-bin batching machine, PLD1600 three-bin batching machine, PLD1600 four-bin batching machine.

4、Cement silo

The cement silo is divided into three types: flake cement silo, integral cement silo, and horizontal cement silo. The upper and lower parts of the cement silo are equipped with level gauges and dust removal systems; in order to prevent the powder from arching, an arch breaking device is installed at the cone part of the silo; it can be designed as a bolted cement silo.

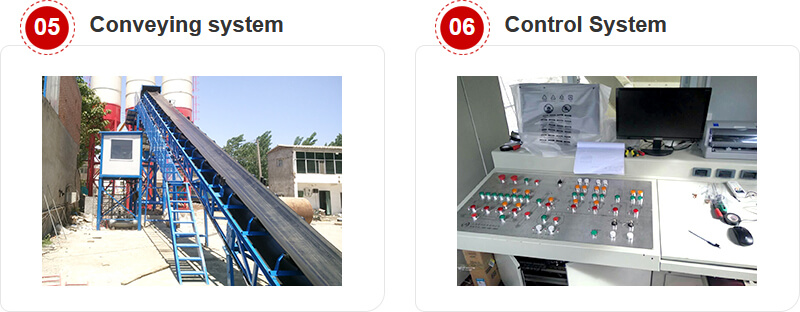

5、Conveying system

The aggregate conveying system adopts the lifting bucket feeding method. The big advantage is that it occupies a small space and saves land resources. The belt conveyor is an ideal efficient continuous transportation equipment, which has the advantages of long transportation distance, large transportation volume, continuous transportation.

6、Control System

The core of 60cbm concrete mixing plant is the control system. The whole machine adopts computer control, which can be controlled automatically or manually. The operation is simple and easy to master. Dynamic panel display can clearly show the operation of each component, and can store and print report data.