The 1500 concrete mixer is a medium-sized mixer, which is mainly suitable for larger construction projects and is a very important construction machinery. It has the advantages of good mixing quality, low energy consumption and high efficiency.

InquiryJS1500 concrete mixer is a large and medium-sized mixer, mainly suitable for larger construction projects.

It is a type of forced horizontal shaft mixer and is a multifunctional mixer. It’s not only mixing dry hard concrete but also mixing lightweight aggregate concrete.

JS1500 Concrete Mixer has the dual advantages of separate operation and can integreted with the PLD series batching machine to form a concrete mixing plant.

Mixing dry hard concrete, plastic concrete, fluid concrete, lightweight aggregate concrete and various mortars.

The product has a rational structure design, a novel layout, conveniently for use and maintenance.

During the mixing process, the mixing blade is driven by the rotating motion of the mixing shaft to carry out the mixing, extrusion, reverse rotation and other mixing actions on the material in the cylinder, so that the material is fully mixed in the relatively violent movement, and thus it has good mixing quality, low energy consumption, high efficiency and so on.

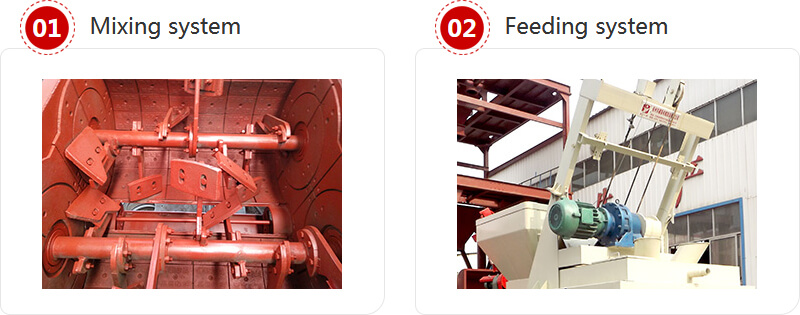

JS1500 concrete mixer Mixing system

The mixing system is composed of an electric motor, a pulley, a speed reducer, an open gear, a stirring drum stirring device, an oil supply device and the like. The motor is directly connected to the cycloidal pin reducer, and the two output shafts of the reducer are driven by two pairs of open gears to rotate the two horizontally arranged stirring shafts at the same speed.

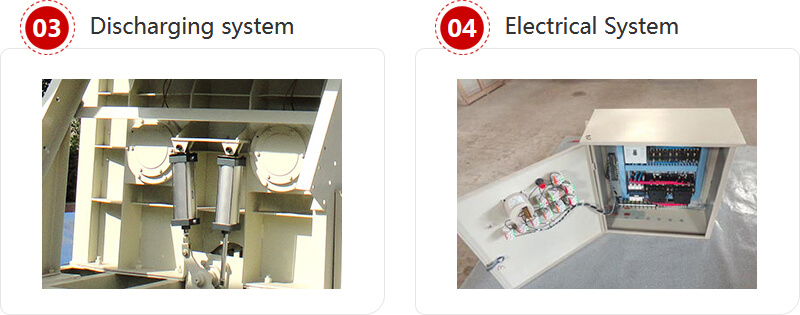

JS1500 concrete mixer Feeding system

The feeding system is composed of a hoisting mechanism, a feeding dragon frame, a hopper, a feeding nozzle and the like. The brake motor drives the reel to rotate through the reducer, and the wire rope climbs along the loading rack rail through the pulley pulling hopper. When climbing to the preset height, a pair of rollers on the bottom door of the hopper enters the water rail of the loading rack, and the bucket door automatically opens. The material is fed into the mixing drum through the feed nozzle.

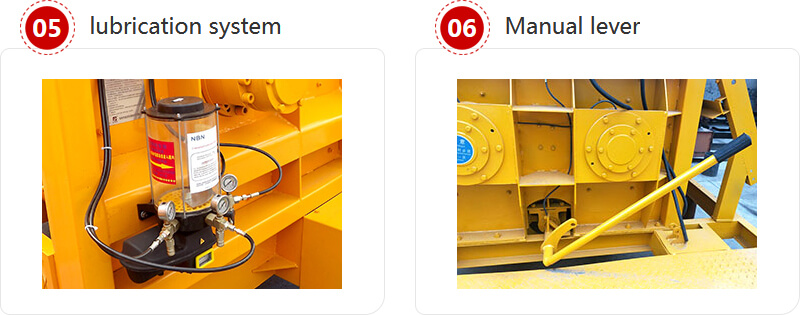

JS1500 concrete mixer Discharging system

The unloading system consists of unloading door, air pump, reversing valve, air valve, cylinder, electrical and other mechanisms.The discharge door is at the bottom of the mixer, and the pneumatic discharge and the opening and closing position of the discharge door are controlled by the cylinder. The position of the sealing strip can be adjusted to ensure the sealing of the discharge door. The unloading manual operating lever of JS1500 concrete mixing station is used for emergency unloading during temporary power failure and cylinder failure. It should be removed in peacetime to prevent injury.

JS1500 concrete mixer Electrical System

The electrical circuit of JS1500 concrete mixer has air switch, fuse, thermal relay, short circuit protection and overload protection. Control buttons and air switch handles and indicators are located on the distribution box door and have a door lock. There is a protective cover on the button.