The 2000 concrete mixer is mainly used in housing construction, bridge and tunnel construction. The use of top materials to achieve a larger space, more energy-saving, more wear-resistant body.

InquiryJS2000 concrete mixer is a kind of machinery which uses pressure to transport concrete along the pipeline continuously. It is composed of pump body and conveying pipe. It is mainly divided into gate valve concrete pump and S valve concrete pump, but according to the structure can be divided into Piston type, squeeze type, hydraulic diaphragm type, the pump body is mounted on the chassis of the car, and then equipped with retractable or inflecting booms, it forms a pump truck, which is mainly used in construction of houses, bridges and tunnels.

The JS2000 forced concrete mixer produced by Jianxin company, is based on the characteristics of domestic concrete raw materials and the production characteristics of the mixing plant. After 20 years of experience in host research and development, combined with advanced foreign research and development technology and the use of the world’s top material, the joint has been carefully created. Advanced concrete mixer equipment. On the basis of having efficient, energy-saving and durable stirring devices, it has a great advantage compared with the same products at home and abroad. The realization of a larger space, more energy-saving, more wear-resistant fuselage, highlights the protection of the new equipment for the quality of customer equipment.

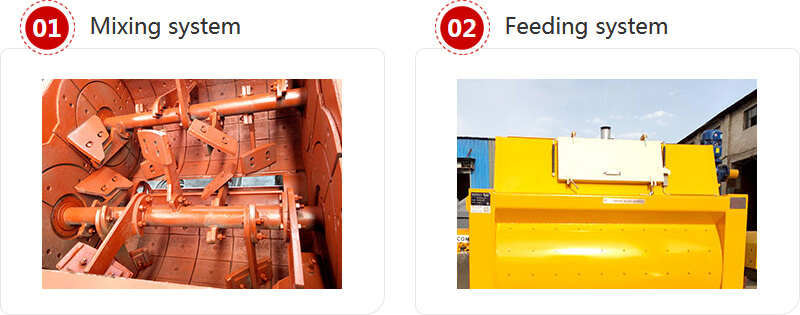

JS2000 concrete mixer Mixing system

The mixing system of JS2000 concrete mixer is composed of electric motor, pulley, reducer, open gear, mixing drum stirring device, oil supply device and so on. The motor of the JS2000 concrete mixer is directly connected to the cycloidal pin reducer. By means of the split gears, the two output shafts of the reducer drive respectively the horizontally arranged agitating shaft to reverse the rotation at the same speed.

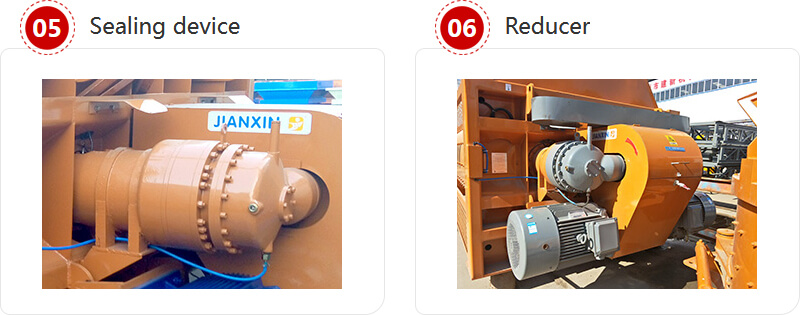

JS2000 concrete mixer Feeding system

The feeding system of JS2000 concrete mixer is composed of hoisting mechanism, loading rack, hopper feeding nozzle and so on. A limit switch is installed on the loading frame, and the upper limit has two limit switches, which respectively paly a role in raising the limit position and safety protection of the hopper with rise of the hopper. The upper part of the loading rack is foldable.

JS2000 concrete mixer Discharging system

JS2000 concrete mixer discharge system consists of unloading hopper, air pump, reversing valve, gas distribution valve, cylinder, electrical and other institutions.

The discharge door of JS2000 concrete mixer is installed at the bottom of the mixer, pneumatically discharged through the cylinder, and can also control the opening and closing position of the discharge door. The position of the sealing strip can be adjusted to ensure the sealing of the discharge door.

JS2000 concrete mixer Electrical System

The electric control circuit is equipped with an air switch, a fuse, and a thermal relay, and has the functions of short circuit protection and overload protection. All control buttons and air switch handles and indicators are placed on the distribution box door with a door lock. A protective cover is placed outside the button. The electrical components in the distribution box are mounted on a single edge plate, which is safe and reliable, and easy to operate and maintain.

JS2000 concrete mixer Manual lever

The unloading manual operating lever of the JS2000 concrete mixer is used for unloading during temporary power failure and cylinder failure. It should be removed in peacetime to prevent injury.