The JS3000 compulsory mixer is a large-scale concrete mixing machine that provides a supporting host. It is suitable for various large, medium and small prefabricated component factories and large industrial and civil construction projects such as highways, bridges, water conservancy, and docks.

InquiryJS3000 Sicoma mixer discharges 3 cubic meters each time, also known as 3 square concrete mixer, the cycle time is 60S. The machine used in 180cbm mixing station . The JS3000 Sicoma mixer is the large model. Mixing machinery, providing supporting host.

Commonly used in mixing station JS3000 Sicoma mixer (3 square concrete mixer) has dual advantages as a single independent operation and also used with the PLD series batching machine ,composed of 180 cbm concrete mixing station , suitable for all kinds of large, medium and small prefabricated factory and Large-scale industrial and civil construction projects such as roads, bridges, water conservancy, and docks. JS3000 Sicoma mixer can be combined with a certain batching machine model to form a large-scale commercial concrete mixing station and a double concrete mixing station, with powerful power and high production efficiency.

The new JS3000 Sicoma mixer is a compulsory, high-efficiency equipment that can produce a variety of concrete, such as plastic, dry hard concrete, high production efficiency, short mixing time, and beautiful appearance, widely used in large and medium-sized construction, roads and bridges. Precast plants for the production of concrete products are ideal equipment for the production of commercial concrete.

JS3000 concrete mixer Mixing system

The arc portion of the mixing drum is welded, and the mixing barrel is provided with five kinds of lining plates, which are fastened with the countersunk screws and the cylinder body.

Due to the different contact conditions between the aggregate and the lining, the lining wear is uneven, and the lining can be exchanged for the purpose of improving the use time of the lining.

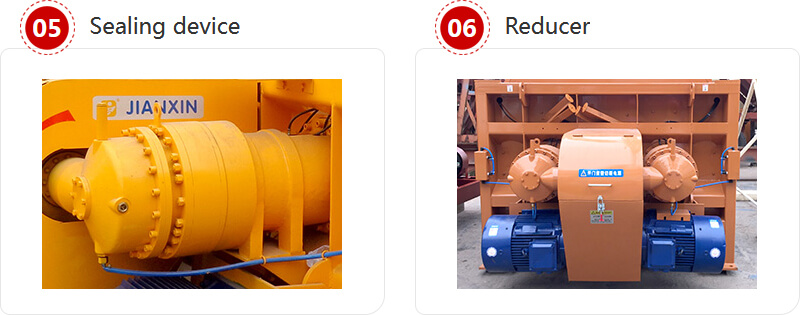

The mixing shaft is provided with a special sealing device at the end of the mixing drum. In order to ensure the quality of the seal, a special oil supply pump is arranged on the end face of the mixer drum.

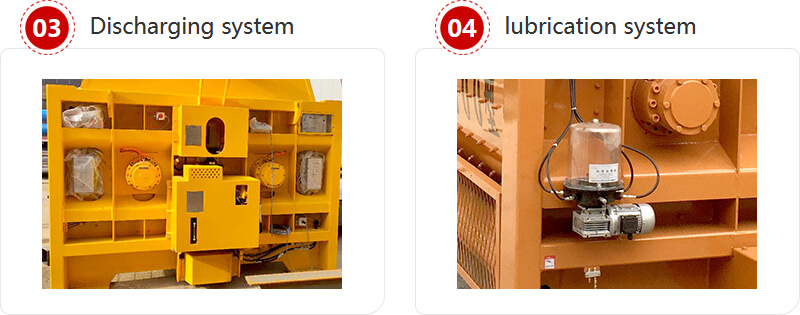

JS3000 concrete mixer Discharging system

The discharging system consists of a discharge door, a gas pump, a reversing valve, a gas distribution valve, a cylinder, an electric mechanism,and other mechanisms.

JS3000 concrete mixer Electrical System

The electric control circuit is equipped with an air switch, a fuse and a thermal relay, and has the functions of short circuit and overload protection. All control buttons and air switch handles and indicators are located on the distribution box door and are equipped with a door lock. The button has a protective cover.